Viscosity tells us how thick or runny a liquid is, and understanding this helps in many industries like food, paint, or medicine. A benchtop viscometer is a small machine that measures viscosity right on your workbench. It’s helpful because it’s easy to use and gives quick answers about how a liquid flows. At ZONWON, we make these instruments to help people trust their measurements every time they test. Using a benchtop viscometer means you don’t have to guess if a material will behave the way you want. This saves time, money, and frustration. You put a sample in, and the machine tells you how thick it is, which is very important to keep products good and safe.

What Makes It Essential for Accurate Rheological Testing

When you want to know how a material flows or stretches, you need more than just a simple guess. Rheology is the science of how materials move, and getting the right answers depends on good tools. A benchtop viscometer from ZONWON is designed to give accurate readings because it controls the speed and measures the force needed to move the liquid. Imagine stirring honey with a spoon you can feel it’s thick, but you can’t say exactly how thick. The Viscometers can do that. It uses parts that spin or move in a very precise way, so the readings are always close to the real thickness. Also, the machine is small but strong, so it can handle many kinds of liquids, from thin water-like ones to thick pastes. Sometimes, temperature can change how thick a liquid is, but ZONWON’s viscometers can keep track of temperature, too, making sure the numbers are right. This matters a lot because if a product like paint is too thick, it won’t spread well; if it’s too thin, it might drip. Getting the right flow helps businesses make the best products. Because the machine is easy to clean and use, workers don’t waste time, and mistakes happen less. Sometimes, people think bigger machines are better, but for many tasks, a benchtop viscometer is just perfect and more practical.

Where to Find Reliable Benchtop Viscometers for Bulk Purchase

If you need a lot of viscometers for your company or lab, finding the right place to buy can be tricky. ZONWON offers a great choice for bulk buying because we understand what industries need. When buying many machines, it’s important that each one works the same way so your team can trust the results no matter who uses them or where they are. We make sure every viscometer matches our high standards. Also, when you order in bulk, prices can be better, and delivery is faster. At ZONWON, we also provide support after you get the machines. This means if there is a question or problem, someone will help you quickly. Some sellers might sell cheap machines, but those often break or give wrong numbers, causing delays and wasted money. Choosing a trusted supplier who knows the work and can guide you through installation and training is a big help. Our customers often tell us how easy it is to work with us because we listen and respond fast. If your company grows, you might need more machines or special parts, and ZONWON keeps that in mind by offering flexible services. Buying from us means you don’t just get a tool; you get a partner ready to help your business succeed.

What Are the Key Features of High-Quality Benchtop Viscometers for Industry Use

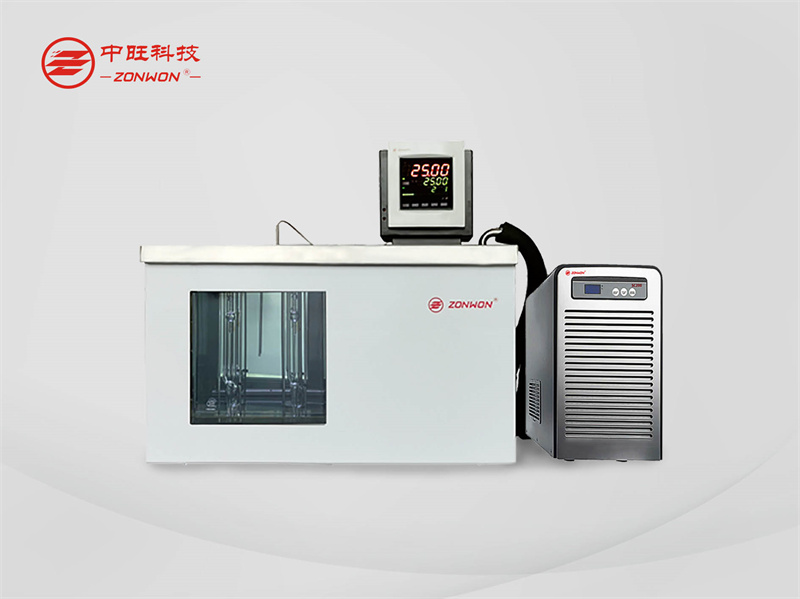

Benchtop viscometers are special tools used to measure how thick or sticky a liquid is. When a liquid flows slowly and feels thick, like honey, it has high viscosity. When it flows quickly and feels thin, like water, it has low viscosity. In industries like food, paint, cosmetics, and chemicals, it is very important to know the viscosity of liquids to make sure the products work well. High-quality benchtop viscometers, like those made by ZONWON, have some important features that help people get the right results every time.

First, a good benchtop viscometer must be easy to use. This means it should have a clear display and simple buttons so anyone can operate it without much training. ZONWON viscometers have easy-to-read screens and user-friendly controls. This helps workers quickly understand the measurements and make decisions faster.

Second, accuracy is very important. The Capillary Viscometer Rack must give results that are close to the true viscosity of the liquid. ZONWON viscometers use precise sensors and advanced technology to make sure the numbers are correct. This is important because wrong readings can lead to bad products or wasted materials.

Third, a high-quality benchtop viscometer should be strong and reliable. In factories, tools are used a lot and can get bumped or dropped. ZONWON makes viscometers with tough cases and materials so they last a long time and keep working well.

Another key feature is the ability to measure different types of liquids. Some liquids flow easily, and some are very thick. ZONWON’s benchtop viscometers can measure a wide range of viscosities, which means they can be used for many different products. This makes them very useful in many industries.

Lastly, the viscometer should be easy to clean. Since many liquids can be sticky or messy, having parts that can be quickly cleaned without damaging the device is a big help. ZONWON designs their viscometers with smooth surfaces and removable parts so cleaning is fast and simple.

In short, a high-quality benchtop viscometer like those from ZONWON is easy to use, accurate, strong, versatile, and easy to clean. These features make it a great choice for industries that need to check liquid thickness carefully.

How Benchtop Viscometers Improve Product Quality Control in Manufacturing

In manufacturing, making sure products are good and work well is very important. Many products, like paint, syrup, lotion, and glue, depend on how thick or thin their liquids are. If the thickness is wrong, the product might not work properly or might not look or feel right. This is where a benchtop viscometer from ZONWON helps a lot. It helps factories control the quality of their products by measuring viscosity quickly and correctly.

When a factory uses a benchtop viscometer, workers can test the liquid during different stages of making the product. For example, in a paint factory, the viscosity of the paint must be just right so it spreads evenly and dries well. Using a ZONWON viscometer, they can check the paint’s thickness every time they make a new batch. If the paint is too thick or too thin, they can fix it before packaging. This stops bad paint from reaching customers.

Benchtop viscometers also help save money. If a company makes a big batch of syrup that is too thick, they might have to throw it away or spend extra money to fix it. By measuring viscosity early with a ZONWON viscometer, they can avoid these problems. It helps catch mistakes early, so less material is wasted.

Another way these viscometers improve quality control is by making the manufacturing process faster and more consistent. When workers know the exact viscosity, they can set machines to work the right way. This means each product batch is very similar to the last one. Customers like this because they trust the product will always be the same good quality.

ZONWON benchtop viscometers also help companies follow safety and industry rules. Many industries have standards that require products to meet certain thickness levels. Using a reliable viscometer shows that the company cares about quality and safety.

ZONWON benchtop viscometers help factories check and control the thickness of liquids. This improves product quality, saves money, speeds up production, and helps companies follow rules. They are an important tool for making sure customers get the best products every time.

Common Usage Issues and Troubleshooting Tips for Benchtop Viscometers

Even though benchtop viscometers like those from ZONWON are made to be easy to use, sometimes people may face problems when using them. Knowing the common issues and how to fix them can help keep the viscometer working well and give correct results.

One common issue is getting inconsistent or strange readings. If the numbers change a lot when testing the same liquid, it might be because the sample is not prepared properly. Make sure the liquid is mixed well and free from bubbles before testing. Air bubbles can make the liquid seem thinner than it really is. Also, make sure the viscometer spindle (the part that goes into the liquid) is clean and not damaged. ZONWON viscometers come with easy-to-clean spindles, so always clean them after each use.

Another problem can be incorrect calibration. Calibration means setting the Capillary Viscometer holder to measure correctly. If the machine is not calibrated often, the results can be wrong. ZONWON provides clear instructions on how to calibrate the viscometer using standard liquids. Follow these steps regularly to keep the device accurate.

Sometimes, the viscometer may not turn on or the screen may freeze. This might be because of low battery or power problems. Make sure the device is charged or plugged in properly. If it still doesn’t work, try restarting it or contact ZONWON customer support for help.

Temperature can also affect viscosity readings. If the liquid is too hot or too cold, the thickness changes. Use the viscometer in a room with stable temperature or use a temperature control accessory if needed. ZONWON offers models that can measure temperature along with viscosity to avoid mistakes.

Lastly, if the viscometer is making strange noises or feels stuck, check for dirt or damage on moving parts. Never use force to turn the spindle. Clean the parts carefully and if needed, get professional service from ZONWON technicians.

In short, the best way to avoid problems with your ZONWON benchtop viscometer is to prepare samples correctly, clean the device regularly, calibrate often, watch the temperature, and handle it gently. These tips will help you get reliable results and keep your viscometer working for a long time.

Comments (0)